-

closeSTÄNG

-

Produkter

-

-

-

-

-

-

-

-

-

Dämpning

-

-

-

Om Vibratec

-

-

NyheterNyhetsarkiv

-

-

-

Våra områden

-

-

-

bild

-

-

-

Kontakta oss

-

-

SverigeHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

NorgeHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

FinlandHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

EstoniaHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

DanmarkHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

IndienHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

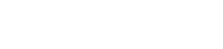

Mer om ossVibratec Akustikprodukter är verksamma inom offshore, varvs- och försvarsindustrin, bygg-, järn- och spårväg- samt reservkraftsbranschen. Vårt breda produktutbud garanterar effektiv vibrationsisolering av allt från små motorer, gasturbiner, broar och järnvägar till hela byggnader.

-

-

-

closeSTÄNG

-

Produkter

-

-

-

-

-

-

-

-

-

Dämpning

-

-

-

Om Vibratec

-

-

NyheterNyhetsarkiv

-

-

-

Våra områden

-

-

-

bild

-

-

-

Kontakta oss

-

-

SverigeHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

NorgeHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

FinlandHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

EstoniaHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

DanmarkHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

IndienHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

Mer om ossVibratec Akustikprodukter är verksamma inom offshore, varvs- och försvarsindustrin, bygg-, järn- och spårväg- samt reservkraftsbranschen. Vårt breda produktutbud garanterar effektiv vibrationsisolering av allt från små motorer, gasturbiner, broar och järnvägar till hela byggnader.

-

-

-

closeSTÄNG

-

Produkter

-

-

-

-

-

-

-

-

-

Dämpning

-

-

-

Om Vibratec

-

-

NyheterNyhetsarkiv

-

-

-

Våra områden

-

-

-

bild

-

-

-

Kontakta oss

-

-

SverigeHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

NorgeHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

FinlandHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

EstoniaHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

DanmarkHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

IndienHantverkaregatan 7

76130, Norrtälje

Tel +46 176-20 78 80

Mail info@vibratec.se

-

-

-

Mer om ossVibratec Akustikprodukter är verksamma inom offshore, varvs- och försvarsindustrin, bygg-, järn- och spårväg- samt reservkraftsbranschen. Vårt breda produktutbud garanterar effektiv vibrationsisolering av allt från små motorer, gasturbiner, broar och järnvägar till hela byggnader.

-

-

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

_1.jpg)

_1.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)