Floor Systems

VT-BAT

Vibratec floor system VT-BAT is a quick and easy-to-install system with discrete isolators. The system comprises of 3 m steel battens with isolators (elastic elements) available in 4 different standard heights: 25, 30, 50 and 75 mm (other heights available on request). Depending on the load and the choice of height resonance frequencies below 6 Hz can be achieved (see frequency curves on next page).

The stiffness ca be adjusted by playing on the number of isolators per m2 or/and by choosing softer/stiffer material for the isolators, please contact Vibratec for advice.

VT-BAT-ST

This is a special version of the VT-BAT system with isolators (elastic elements)

in stainless steel mesh. The system is therefore suited to applications where with stringent environmental requirements such as food processing industry or harsh environments where the isolators might be exposed to chemicals or high temperatures.

These type of isolators have high internal damping plus very progressive load- deflection characteristics resulting in a quite stable resonance frequency over a big load range. These dynamic features make the system also suitable in mobile applications with varying or heavy dynamic loads such as floors in train cars, machine halls, ships and offshore platforms.

VT-FLOAT

A system for heavy floating concrete floors with either elastic pads or steel springs as discrete isolators. VT-FLOAT is used in cases with high requirements on airborne and impact noise isolation. The system can either be delivered as pre-manufactured, uniquely marked panels (with isolators and mineral wool glued to the board), or as separate components.

By adding extra isolators the system allows easy adjustment of the stiffness on different parts of the floor (due to extra linear or point loads for instance).

The elastic isolators are available in standard heights 50 and 75 mm reaching a resonance frequency of 6 Hz (other heights on request).

The steel springs are available in standard heights 100 and 150 mm reaching a resonance frequency of 5 and 3,5 Hz.

Heavy floating concrete floors are often required in applications such as bowling lanes, cinema halls, gym floors, discotechs, machine foundations etc. Vibratec can also offer the on-site installation of the system plus verification measurements of Ln and Rw.

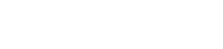

VT-BOX

VT-BOX is an anti-vibration, height adjustment system for heavy floating concrete floors and slabs. VT-BOX is used in cases where a heavy floating floor is needed but the building height has to be kept at a minimum. The boxes can be used for concrete thicknesses 120 – 300 mm, static loads from 300 kg to 2000 kg per box and adjustment up to an air void gap of 30 mm. Resonance frequency 3 – 6 Hz.

Diagram

Guidelines

All Vibratec floating floors are designed to deflect under load, i.e. the floating floor must be allowed to move.

The floating floor should therefore have no contact with surrounding structural walls. In cases with floating floor in concrete a formwork is used along the perimeter of the floor. In case the floor shall meet an existing wall, pillar or similar, an elastic mat or a mineral wool can be used as “lost formwork”.

Low density mineral wool should be installed between floor battens or isolators. The mineral wool will decrease the standing wave effect in the air void between floating floor and structural floor.

It is important that all building parts penetrating the floating floor do not have any direct contact with the floor. Pillars, pipes, ducts etx therefore must be kept separated from the floor by use of elastic mats in PU-foam or mineral wool. Any direct contact will cause acoustic bridging and decreased performance of the floating floor.

When building a room within a room the inner walls are often put on top of the floating floor, meaning the load from the walls shall be carried by the floating floor. This extra linear load must be considered (as well as other permanent loads from for instance tiered seating, scene, loudspeakers) by introducing battens or extra isolators.